In a year when the EU’s Ecodesign for Sustainable Products Regulation prioritizes textiles as a key sector with mandatory Digital Product Passports rolling out by 2027, the answer is a big yes.

The global DPP market is projected to grow from USD 185.9 million in 2024 to USD 1,780.5 million by 2030, with textiles alone valued at around $2 billion in 2025 and expanding at a 25% CAGR. Early adopters can turn this mandatory compliance need into a competitive edge against greenwashing, counterfeit risks, and the textile sector’s 92 million tons of annual waste.

While the EU has introduced laws like the Circular Economy Plan and the Ecodesign for Sustainable Products Regulation (ESPR) to address these issues, do not assume it is just an exclusive European textile manufacturing issue. Exports to EU will also require adherence to DPPs. The American Apparel & Footwear Association is also pushing FTC for digital labeling. So, faster than we anticipate, this legislation could be adopted on a global scale.

This is why brands like Moncler, Prada, Louis Vuitton are starting to utilize blockchain-based DPPs to provide tamper-proof, scalable, and transparent solutions that work across borders.

The potential here is obvious. Those who adopt won’t just meet ESPR requirements. They will win trust, bring in ESG-focused investors, and strengthen their position in a stressed market.

In this article, we will explain the importance of this change, what all can be done, and how it can build your brand’s strength over time.

A Refresher: What Is a Digital Product Passport?

Digital Product Passports (DPPs) is a machine-readable record that captures a product’s entire lifecycle, from raw material sourcing and manufacturing to use, repair, and end-of-life disposal or recycling. DPPs are a cornerstone to enhance product circularity and reduce environmental impact across multiple sectors.

Initially prioritized for high-impact industries like, textiles, batteries, electronics (including ICT products), tyres, furniture, toys, detergents, and cosmetics, with mandatory rollout starting in 2026-2027 for priority categories. Later, DPPs will likely extend to automotive, construction, and chemical industries as well.

Read More: Blockchain for Digital Product Passports: Which Use Case Hits Billions First?

DPPs follow established standards like ISO/IEC 15459:2015 for unique identifiers and use JSON/UML for lifecycle modeling to help you track and verify product data. This means that every product receives a distinct ID, QR code, NFC, or RFID, linking to critical data points such as material source, harmful substances, carbon emissions, repair guides, and compliance information.

This works, but it has limitations as data can be tampered with, and coordinating between multiple stakeholders can be slow and complicated.

This is why blockchain-based DPPs are gaining good attention. They store proofs and data hashes on a blockchain that cannot be changed, making the information secure, traceable, and easy to verify among different groups. Systems like IPFS handle large files such as images or certificates, making it possible to scale without issues.

These DPPs integrate seamlessly with ERP like legacy systems and regulatory platforms via APIs, so you don’t have to juggle multiple data bases or back-office systems. Regulators and auditors get full access to detailed datasets, while consumers see simplified, verified information they can actually trust.

Let’s move to textile DPP now.

Why Textile Leaders Can’t Ignore Digital Product Passports?

The textile industry, valued at $1.11 trillion in 2024, is grappling with major issues. Since 2000, production has more than doubled, while yearly waste has climbed past 92 million tons. The industry generates around 10% of global emissions but recycles under 1% of its materials. Scandals like the Rana Plaza disaster and forced labor tied to Uyghur cotton highlight deeper failures in the system.

Here are a few main reasons that we need DPP in textiles to solve transparency and complexity in traceability issue:

1. Supply chains are messy

Fashion supply chains have always been complex, and they’re only getting harder to manage. In the past two decades, EU exports of used textiles grew from 550,000 tons to 1.7 million tons. That’s why the ESPR now mandates DPPs on all items, which include details like where they’re from, what they’re made of, and how they affect the environment.

The main challenge lies with disconnected systems because suppliers, subcontractors, and transport partners in the lower tiers do not use digital tracking, which creates a major visibility gap.

At its root, this stems from a multifaceted, buyer-driven network of global tiers—

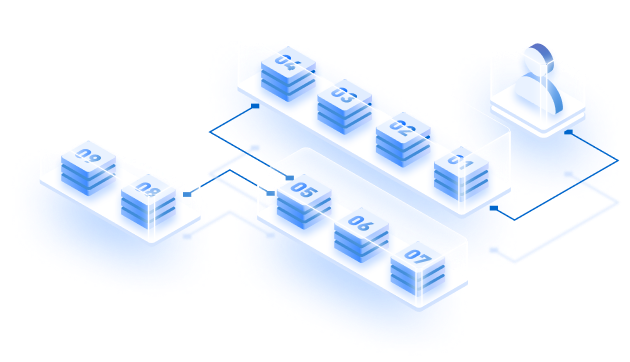

From raw material farms and petrochemical plants (Level 4) → to yarn spinners (Level 3) → fabric weavers (Level 2) → garment assemblers (Level 1) → and brands at retail (Level 0)—where manual logs, paper trails, and siloed vendors obscure upstream risks like unethical sourcing, intense water/land use, and environmental shortcuts.

These leaves brands exposed to reputational damage, regulatory blind spots, and the full weight of fast fashion’s unrecyclable waste.

2. Data is unreliable

As per The Business of Fashion and McKinsey and Company, 2019 report, around 52% of millennials, 45% GenZ and 41% baby boomers, always research backgrounds before buying textiles. But only about 17% of textile companies share accurate traceability data online, and that’s where things start to break down.

Traditional DPPs use standards like GS1 EPCIS to enable data exchange, but many smaller suppliers struggle with the technical setup. This results in messy or incomplete data. Carrying out audits also takes a lot of effort, and this makes small companies less likely to commit.

At the core, unreliable data comes from inconsistent capture methods. Spreadsheets are prone to errors, verbal handoffs, and self-reported certifications that can’t be cross-verified—all of which fuel distrust from regulators and buyers, inflate costs through endless manual checks, and hinder informed decisions amid rising consumer scrutiny.

3. The Booming Second-Hand Market Demands More Transparency

Globally, the second-hand apparel market is set to hit $367 billion by 2029, growing at about a 10% compound annual growth rate (CAGR). That’s way faster than the regular clothing market.

In the U.S., it jumped 14% in 2024 alone, going from $49 billion that year to a projected $74 billion by 2029. And who’s fueling this? Gen Z and millennials. With over 68% of them buying secondhand apparel in 2024, up from the year before, because they see it as a smart, eco-friendly way to get unique pieces without the guilt. In fact, 83% of Gen Z either already shop secondhand or want to, putting them ahead of other age groups by about 11%. By 2030, Gen Z’s spending power could reach $12 trillion worldwide, so ignoring this crowd means brands are leaving money on the table.

DPPs can double a product’s lifetime value, and consumers will claim a majority of this new value.

Source: Bain & Company Report.

Phased implementation plan for EU DPP

Choose the Right DPP Stack for Your Textile Business

When we began creating a DPP solution, we saw early on how your chosen approach can transform everything. It affects more than just the tech side. It shapes the level of control, trust, and clarity you’re able to achieve. Here are two ways you can integrate DPP in your systems

1. Traditional DPPs

Most companies still rely on centralized databases with ERP or PLM systems, Where Products are linked via QR codes, barcodes, or RFID tags, and data sits in a central server with basic encryption.

Here is why most founders like it:

- Quick to deploy if your supply chain is mostly trusted

- Low upfront cost, integrates with existing systems

But, they don’t see this coming:

- Gaps in lower-tier suppliers make ESG tracking incomplete

- Traceability is often limited

2. Blockchain DPPs

This method uses blockchain to create secure permanent records while keeping sensitive details off the chain. Smart contracts handle lifecycle with AI or analytics tools, and you’re not just tracking, you’re predicting and optimizing every step of your supply chain.

That’s why blockchain for sustainable supply chains hit $827.6M in 2024 and is growing 35.1% CAGR through 2032. More than 150 companies in the EU’s CIRPASS consortium are already testing this across apparel and electronics. Founders can turn blockchain into more than just a tool to follow rules. It becomes a way to gain insights and make better choices in operations and product design.

Trace Your Fashion. Verify Its Impact. @OpenledgerHQ

— 0xMistBlade 🗡️ (@0xMistBlade) September 5, 2025

Tracking sustainability in fashion has always been a challenge too often, brands claim eco-friendly practices without clear proof. OpenLedger’s Proof of Attribution changes that.

By securely recording every step of the… pic.twitter.com/CupyY51nNh

If you’re thinking about Digital Product Passports (DPPs) for actions like PRODUCED and RECYCLED, DIDs and VCs take care of identities, and ZKPs let users confirm details without sharing confidential information.

Why it’s important for you:

- Provides full visibility throughout the supply chain.

- Cuts down on fraud and helps build trust with partners.

- Makes ESG claims provable and supports token-based rewards.

How Blockchain DPP Can Transform Your Textile Business

Let me tell you why blockchain-powered Digital Product Passports (DPPs) are game-changers for your products, because when your products have a secure, verifiable digital identity that is easy to track and cannot be altered, everything changes.

1. Complete Traceability for All Products

With blockchain DPPs, every fiber, dye, and fabric gets its own digital record, right from the cotton fields to the final stitched piece. That means your buyers, partners, or regulators can simply scan a QR code or tap an NFC tag and see the entire journey instantly. With this, it’s not just about meeting rules; it’s about showing authenticity on demand. For example,

Moncler, a leading luxury brand, implemented blockchain DPPs via partnerships with Certilogo and Arianee, and embedded NFC tags in jackets for full traceability from raw materials to end-user. This not only verifies authenticity but also supports resale by preserving product history, reducing counterfeiting risks without relying on traditional centralized systems.

🎙️ Let's talk about…@LoroPiana's Digital Product Passport

— LVMH (@LVMH) June 13, 2025

Loro Piana has implemented a QR code, capable of revealing the full journey of its luxury fibers, from source to finished product, leveraging blockchain technology to prove authenticity and enhance the client… pic.twitter.com/7vF6AqfRB8

LVMH-owned Loro Piana also adopted blockchain for its high-end ‘The Gift of Kings’ line to ensure provenance tracing and verifiable ownership. They preferred blockchain for its decentralized security over vulnerable centralized databases.

2. Prove your sustainability without guesswork

We all know that producing textiles uses a lot of resources. Just one kilogram of cotton can require about 20,000 liters of water, and the industry generates 92 million tons of waste every year.

That’s why we use Blockchain DPPs, which let you prove your sustainability claims. Just by integrating this, you can track the water, energy, and carbon footprint of each item. Add smart contracts, and you can even reward recycling or take-back programs through token-based incentives.

For example, H&M’s TextileGenesis now covers 89% of products with sustainable fibers in 2025. It verifies recycled polyester for over 200 million items. Haelixa joined them in October 2025. They link DNA tests to blockchain for material proof from farm to shop.

Prada’s Re-Nylon line also shows ocean plastic recycling paths. Blockchain seals the eco-story for buyers.

3. Compliance Made Simple

By 2027, over 1 trillion products will need DPPs, including 62.5 billion textile items, because the EU’s ESPR calls for clear and open practices in the fashion and textile world. We recommend Blockchain-based DPPs that record trustworthy product details on-chain, building permanent audit trails that cannot be altered.

With the help of APIs, it’s easier to link these systems with ERP and PLM software to automate reporting duties. This setup cuts the chances of penalties by sharing data in a privacy-friendly way, and Founders can manage compliance efficiently without it becoming a daily struggle.

For example, by mid-2025, Louis Vuitton has registered over 70 million items with instant authenticity checks that fit CIRPASS standards. And they have used Aura Blockchain Consortium for it.

4. Save time and boost efficiency

Most textile teams waste hours reconciling supplier data, certifications, and audit reports. It’s slow, manual, and expensive. By using Blockchain DPPs, we can easily automate that. Smart contracts take care of supplier checks, emission reports, and certification validation, and add multi-party computation (MPC), with just that suppliers can collaborate on shared insights without exposing private data. The result is Faster audits, fewer disputes, and lower costs.

For example, Lenzing, which is a 1938 Austrian fiber producer with Platinum EcoVadis status, integrates blockchain via TextileGenesis for TENCEL fiber tracing. They cut verification time by up to 50% in 2025 pilots through immutable ledgers and real-time data flows across supply tiers.

A few more examples could be: Moncler’s NFC-enabled Digital Product Passport automates ownership transfers for resale and cuts manual processes. Prada’s Aura integration makes audit simple across suppliers, and Louis Vuitton’s blockchain prototypes reduce reconciliation time for handbag provenance.

5. Stand out in the market

Once your product has a digital identity, it becomes more than just inventory, it becomes an interactive, verifiable asset. Even Luxury or eco-friendly editions can be tokenized, authenticated, and sold as collectible or traceable items.

Projects like VeChain’s collaboration with Empoli FC or DRESSdio’s NFT outfits are proving that this connection between digital and physical products drives engagement and loyalty.

A big congratulations to the @wovlabs_com team for their incredible work as they join hands with @EmpoliFC to integrate their digital passport solution directly in Soccer Jerseys.

— VeChain (@vechainofficial) August 27, 2024

Powered by NFC and VeChain's blockchain, the solution is well-positioned to benefit from a major… https://t.co/O9ahwin9H5

Even H&M’s take-back service now uses blockchain to verify recycling returns, offering discounts and loyalty points. Levi’s is testing similar tracking for denim, ensuring every material can be recycled with confidence. That’s differentiation at a product level.

6. Make Decisions with Data

Every product creates reliable and clear data. This helps you track supplier reliability, forecast sustainability targets, and spot inefficiencies early. Pair your brand, here’s the reality: most companies struggle to connect supply chain data with blockchain in a way that’s actually usable.

Here’s my take as a fellow builder: DPPs aren’t just about ticking regulatory boxes; they’re about building trust, unlocking resale opportunities, and scaling efficiently.

Build Your Digital Product Passports with Zeeve

At Zeeve, we handle the infrastructure so you can focus on your product and growth. With experience from 300+ deployments for enterprises like CodeNekt, Vodafone, DCB Bank, and Tassets, we help brands implement DPPs that:

- Connect IoT and blockchain data across the supply chain for real-time insights

- Track resales using ERC-1155 NFTs to generate new revenue streams

- Start small with a pilot SKU, measure results, then expand at scale

- Our infrastructure is ISO 27001 and SOC 2 certified, ensuring your data and operations are secure while you innovate.

We make DPPs practical, measurable, and hassle-free. If your goal is to lead this transformation, our team can help you get there without the usual headaches.

Reach out to explore how your brand can lead this transformation.